Functional Master Batch

*For newly developed products with special specifications.

TPU / PE

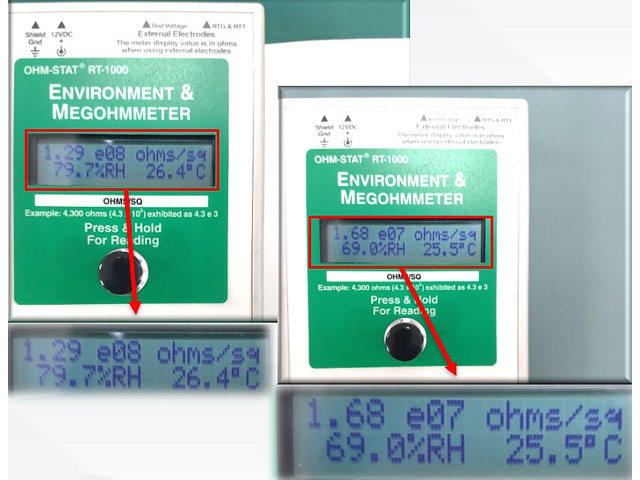

(1). Reduce electrostatic charge accumulation.

(2). Long-lasting, transparent, non-migrating.

(3). Thickness 0.1mm, surface resistance can be ≦109-10Ω/sq

*Long-lasting type, surface resistance can be≦108Ω/sq.

Flame Retardant

TPU / PE

(1). Halogen and heavy metal free.

(2). Good dispersion, no migration and precipitation.

(3). Product thickness 1.0mm can reach UL-94 V0 level.

*Can pass the aviation equipment FAR 25.853 combustion test.

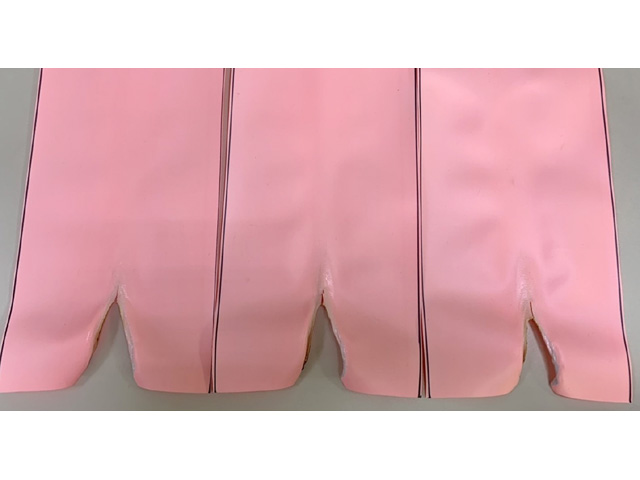

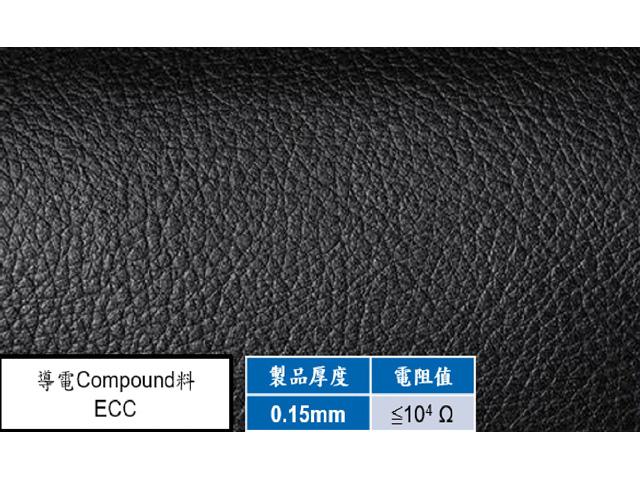

TPU / PE

(1). Black conductive material.

(2). There are different conductive specifications to choose from.

*The surface resistance of foamed products can be≦104Ω/sq.

TPU

(1). Give the product anti-stick or smooth effect.

(2). Good physical properties, good dispersion, not greasy.

(3). Improve the processability during production.

*The raw material complies with FDA regulations.

TPU

(1). Give the product a matte or matte effect.

(2). Good physical properties, good dispersion.

(3). Does not affect the touch of the surface of the product.

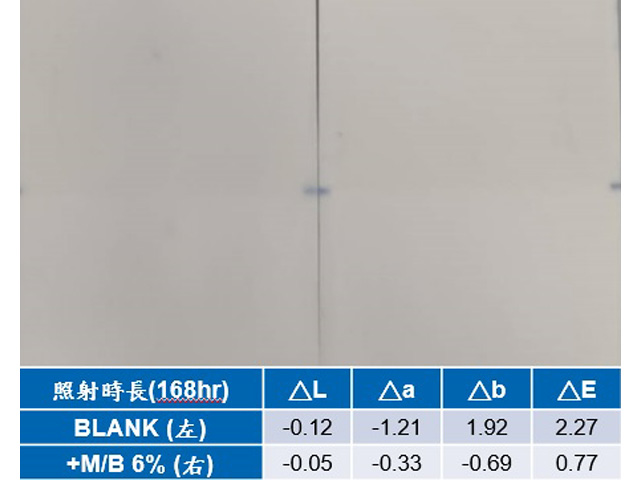

TPU / PE

(1). Comply with EU REACH SVHC substance regulations.

(2). Strengthen the product's light fastness and weather resistance.

(3). Colorless, low impact on color.

(4). ISO 105 B02 testing, up to level 4.

*Complies with AFIRM substance specification.

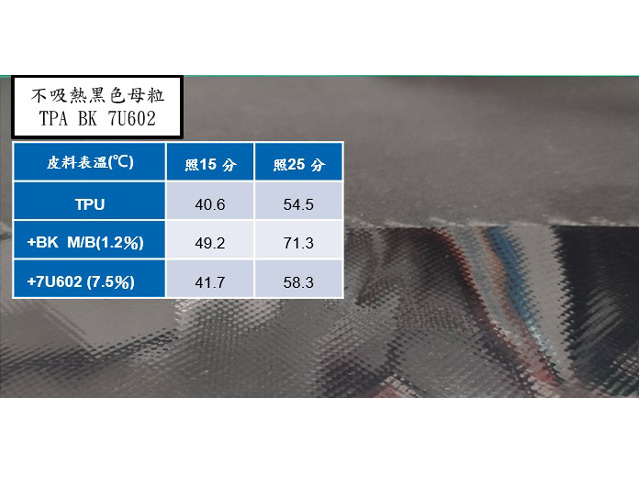

TPU

(1). Slow down the rate of heat absorption and temperature rise.

(2). Good blackness.

(3). High IR reflectivity and low heat absorption performance.

(4). There can be a temperature difference of more than 10°C.

TPU / PE

(1). Non-toxic and high temperature resistant.

(2). Good transparency.

(3). Prevent the growth of microorganisms and bacteria.

(4). The antibacterial effect is over 99.9%.